Ingersoll Cutting Tools

Rotem offers cutting tools by Ingersoll Cutting Tools to companies across Ontario and Canada. Ingersoll is known for their high quality products. We offer indexable inserts, endmills, slotting cutters, jet spindles, and more, but our product list is always growing! Contact us if you are interested in a product you don’t see here or to get more information.

Indexable Inserts

Indexable Inserts

- Top quality carbide materials used

- Variety of sizes, grades and chipbreakers for every job

- Supplied by Ingersoll Cutting Tools

- Save money on jobs by implementing quality North American made products

- Same day shipping

For optimizing your production and lowering costs, we offer a variety of indexable inserts and cutting tools for all of your machining requirements. We carry the best from Ingersoll Cutting Tools for indexable inserts. When buying from Rotem, you can rest easy knowing you’re getting quality products at competitive pricing.

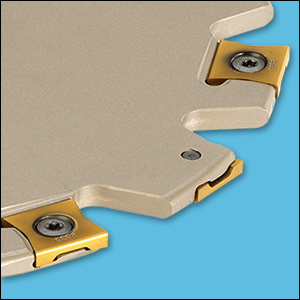

Gold Line Slotting Cutter

- Rigid, secure insert seating

- Significant advances in durability, accuracy, and rigidity

- Diameters ranging from 1.50″ to 8.00″

- Cutting widths of .125″ to .500″

- Multiple corner radii

- Same insert used in RH and LH stations

Quad Feed Cutters

Quad Feed Cutters

- Robust thick insert design.

- Larger, stronger insert geometries promote longer tool life.

- Strong clamping screw for demanding applications.

- Ultra reliable machining performance at high feed rates.

- Premium milling grades to cut all materials.

- Latest post coat technology, provides superior bonding between the substrate and the coating layer.

- New 9mm Insert Expansion

- Positive axial, high-feed technology.

- Ultra-strong super-free cutting insert geometry.

- 4 indexes per insert.

- 2 different insert geometries for application flexibility.

- Face Mill, End Mill and Top-on systems.

- Premium milling grades ensures long lasting performance.

- Diameters ranges: 1.250, 1.500, 2.000, 2.500, and 3.000 inch.

- Higher cutter densities.

- Lower cutting forces.

Innovative High-Performance Solid Carbide End Mills

Innovative High-Performance Solid Carbide End Mills

- Combo high-feed variable pitch chipsplitter

- 4- and 5-flutes with 38° and large corner radii

- An end mill that provides the greatest advantage in

cavity milling and heavy roughing cuts - The serrated cutting edge features flat peaks which

leave a better surface finish when compared to

competitors’ roughing end mills - Chatter-free

- Diameters from .250″ to .750″

Ingersoll’s series 45D…RP solid carbide roughing endmills give you the optimal solution for all roughing operations. This series covers a wide range of applications including slotting, pocketing, helical interpolation and contouring. Features and Benefits • 4- and 5-flutes with 38° and large corner radii • An endmill that provides the highest advantage in cavity milling and heavy roughing cuts • The serrated cutting edge features flat peaks which leave a better surface finish when compared to competitors’ roughing endmills.

Ball Nose End Mills for 3D Contour Milling

Ball Nose End Mills for 3D Contour Milling

- Ultra-stable clamping system and excellent repeatability

- Through-the-tool coolant, delivered to the cutting edge

- Premium ground cutter bodies

- Ball nose and backdraft coolant-through insert styles

The 12A5, 12A8 and 12A9 series Ball Nose are the newest edition to the Ingersoll Die & Mold contour milling offering. This exciting new technology is packed with features to deliver performance and productivity.

- Reduced machining time (high speed table due to high rotation)

- Energy saving (machine spindle is idle while Typhoon is active)

- Excellent surface quality due to optimized conditions

- Plug & play installation on existing machines

- Extended tool life due to optimal conditions

- Up to 65% increased efficiency versus original low RPM machine

- Direct wireless rotation speed display

Ingersoll Cutting Tools’ Typhoon utilizes unique high-speed compact spindles to leverage your original machines coolant supply to upgrade performance. If you are looking to extend the life of your original machine while increasing production, the Typhoon is a great solution. It can be used for a variety of applications which including milling, thread milling, drilling, grinding, chamfering and engraving. An innovative machine, it will help reduce costs and improve efficiency for your production line. And when buying from Rotem, you can rest easy knowing you’re getting quality products at competitive pricing.

Order before 2:00 pm today to get same day shipping on your order.

You must be logged in to post a review.

Reviews

There are no reviews yet.